What is CPR?

With new CPR (Construction Products Regulation) rules being implemented by the European Commission (EC), construction products – including cabling for fixed installations – can no longer be used in European buildings or civil engineering works if they are not tested and certified according to the new CPR rules.

Replacing the Construction Products Directive (CPD), which was first published by the EC in 1989, CPR is already applicable for non-cable products since July 2013.

The official CPR introduction for cables was 10th June, 2016, following which manufacturers were given a 12-month transition period to ensure all cable products comply.

CPR ensures that distributors, consultants, systems integrators, installers and building owners have reliable product information from different manufacturers in different countries to make accurate product comparisons. This will allow for free movement of all construction products within the European Union.

When does CPR become applicable?

CPR has officially come into force as of June 10, 2016. The transition period will end one year later, in July 2017.

CPR for groups?

CPR language applies to architects, engineers, contractors, member states, manufacturers and end users. It must be used when specifying requirements and selecting products.

What does CPR mean for manufacturers?

Before placing a product on the market, there are certain rules that manufacturers must follow:• Issue a Declaration of Conformity/Performance stating the Euroclass performance of the specific product.• Affix the CE marking and keep all documentation for 10 years.• Monitor the product (including self-testing of samples) following additional Assessment and Verification of Constancy of Performance requirements.• List contact information of the product.• Provide instructions and safety information in appropriate language.•Take corrective measures when necessary and cooperate with any requests from authorities.

The main standard

1.EN 50575 Power,control and communication Cables-Cables general applications in construction works subject to reaction to fire requirements. 2.EN 13501-6 Fire classification of construction products and building elements-Part 6:Classification using test data from reaction to fire tests. 3.PD CLC/TS 50576 Electric cables-Extended application of test results.

Standard and project

| CLASS | ENISO 1716 | EN 50399 | EN 60332-1-2 | EN 61034-2 | EN 60754-2 |

| Aca | X | ||||

| B1ca | X | X | # | # | |

| B2ca | X | X | # | # | |

| Cca | X | X | # | # | |

| Dca | X | X | # | # | |

| Eca | X | ||||

| Fca | X | ||||

| X=MUST PASS #=ADDITIONAL CLASSIFICATION | |||||

TEST METHODS

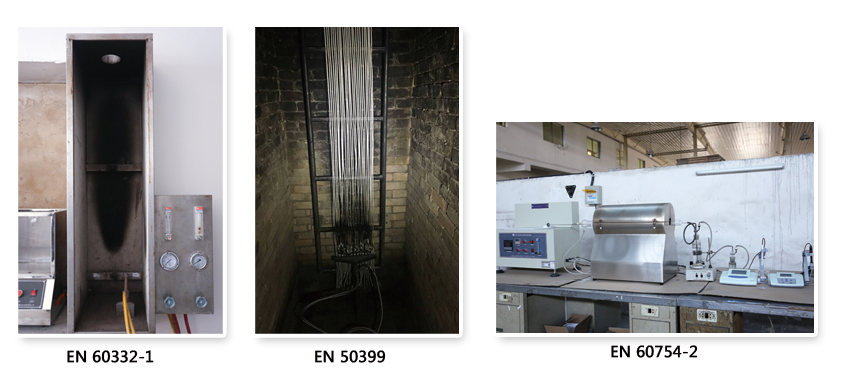

EN 50399EN 60332-1-2 EN 61034-2 EN 60754-2(contains all the information previously contained in EN 50267-2-3)EN ISO 1716

TEST

| CLASS | Aca | B1ca | B2ca | Cca | Dca | Eca | Fca |

TEST METHOD(S) |

EN ISO 1716 |

FIPEC20 Scen 2 (5) |

FIPEC20 Scen 1 (5) |

FIPEC20 Scen 1 (5) |

FIPEC20 Scen 1 (5) |

EN60332-1-2 |

NO |

EN60332-1-2 |

EN60332-1-2 |

EN60332-1-2 |

EN60332-1-2 |

||||

CLASSIFICATION CRITERIA |

PCS ≤2,0 MJ/kg(1) |

FS ≤1.75m and THR1200s≤10MJ;and Peak HRR≤20 kW;and FIGRA ≤ 120Ws-1 |

FS ≤1.5m and THR1200s≤15MJ;and Peak HRR≤30 kW;and FIGRA ≤ 150Ws-1 |

FS ≤2.0m and THR1200s≤30MJ;and Peak HRR≤60 kW;and FIGRA ≤ 300Ws-1 |

THR1200s≤70MJ;and Peak HRR≤400 kW;and FIGRA ≤ 1300Ws-1 |

H ≤ 425 mm |

|

H ≤ 425 mm |

H ≤ 425 mm |

H ≤ 425 mm |

H ≤ 425 mm |

||||

ADDITIONAL CLASSIFICATION |

Smoke production (2,6) and Flaming droplets/particlse (3) and Acidity (4,8) |

Smoke production (2,7) and Flaming droplets/particlse (3) and Acidity (4,8) |

Smoke production (2,7) and Flaming droplets/particlse (3) and Acidity (4,8) |

Smoke production (2,7) and Flaming droplets/particlse (3) and Acidity (4,8) |

|||

ADDITIONAL CLASSIFICATION- Smoke density (EN13501-6) S1:TSP1200S≤50m and Peak SPR ≤0.25m /s Practical protocol :run EN 50399 ladder test first, check result is s1,and if so run EN61034 test |

ADDITIONAL CLASSIFICATION d0:No flaming droplets/particles within 1200s Pracitcal protocol :monitor EN 50399 test for flaming droplets and if any,or >10s,then ignore rest of test |

||||||

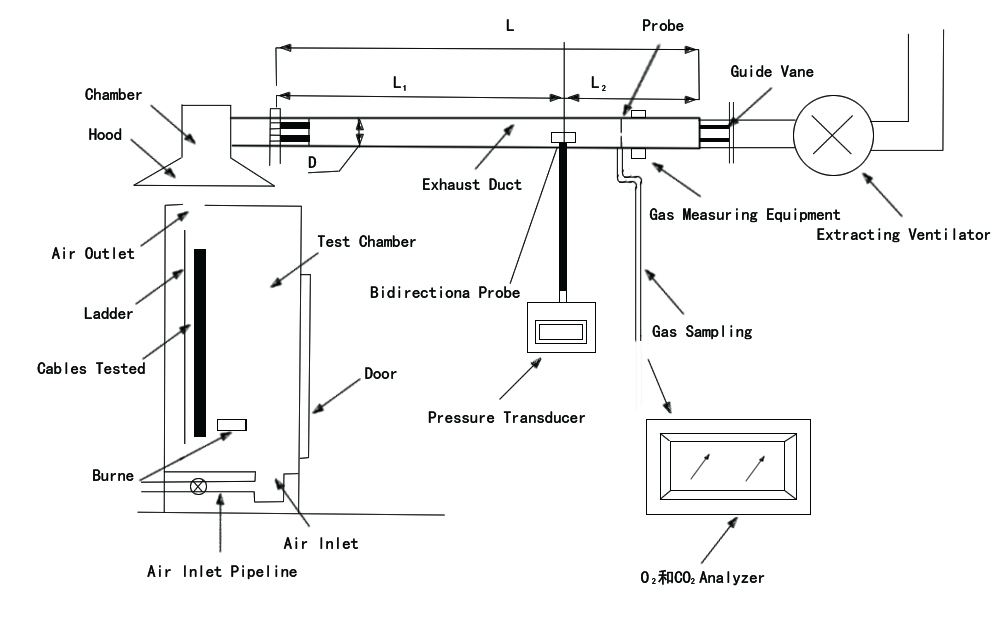

design diagram

Class about HaiTang Cables

| B2ca | Cca | Dca | Eca | |

| CAT6 U/UTP | √ | √ | √ | √ |

| CAT6 U/FTP | √ | √ | √ | √ |

| CAT6A U/FTP | √ | √ | √ | √ |

| CAT6A S/FTP | √ | √ | √ | √ |

| CAT7 S/FTP | √ | √ | √ | √ |

| CAT7A S/FTP | √ | √ | √ | √ |

| CAT8.2 | √ | √ | √ | √ |

| CAT6 U/UTP (uncontinual AL-foil) |

√ | √ | √ | √ |

| CAT6A U/UTP (uncontinual AL-foil) |

√ | √ | √ | √ |

| CAT6 F/FTP | √ | √ | √ | √ |

| CAT6A F/FTP | √ | √ | √ | √ |

| CAT7 F/FTP | √ | √ | √ | √ |

| CAT7A F/FTP | √ | √ | √ | √ |

| CAT8 F/FTP | √ | √ | √ | √ |

| CAT6 F/UTP | √ | √ | √ | √ |

| CAT6A F/UTP | √ | √ | √ | √ |

| CAT6A U/UTP | √ | √ | √ | √ |

| CAT5E U/UTP | √ | √ | √ | √ |

| CAT5E F/UTP | √ |

What has Haitang cable done to comply with CPR?

Haitang cable has made significant investments in both state-of-the-art equipment and dedicated resources, to ensure its’ products comply with CPR rules. There are now, in-house fire-testing capabilities for Haitang cable’s cabling products to be tested as well as work with notified bodies to ensure Haitang cable products meet the requirements necessary for approvals. A cross functional team worked with contacts across the EU to understand the differing requirements.

Haitang cable followed a demanding test schedule between 2015 and 2017 to ensure its products were tested and comply with CPR rules prior to the lapse of the grace period 1st July 2017 and will continue to do so for all CPR products. In line with AVCP requirements Haitang cable can demonstrate its products comply to CPR and can supply CE markings and Declaration of Performance certificates for its products.

How can Haitang cable help make sure I comply with CPR?

From end users and consultants to systems integrators and distributors, Haitang cable has the knowledge to help all team members successfully deal with new CPR requirements. A CPR “mini guide” has been made available by Haitang cable, offering all parties the information they need about CPR background, regulation details and implications of the new rules.

Haitang Cable Prepares for CPR Rules

To make sure all Haitang cabling products comply with necessary CPR rules, Haitang cable has been working diligently.

By making investments in state-of-the-art equipment and dedicated resources, we’ve set up an in-house testing site,to measure Haitang cabling product reaction to fire tests per EN 50399 standards, including:Heat release,Flame spread,Smoke production,Flaming droplets.

How do Euroclasses compare with other (international) fire standards?

CPR Euroclasses address all aspects of a cable’s behavior during a fire. Behavior is measured against time on real size samples.

Euroclass Eca is defined with reference to IEC/EN 60332-1-2. For the other classes there is no direct relationship between existing IEC test and CPR. The basic structure of the testing rig is the same, but because of differentmounting requirements and the use of new parameters, the test results are not comparable.

After July 1st, the use of IEC standards on CPR applicable cables is prohibited.

What is a CE marking?

The CE marking allows a product to be placed legally on the market in any member state. It indicates that a product is consistent with the manufacturer’s Declaration of Conformity/Performance.

Which cables are involved in CPR?

All power, control and communication cables that are installed in fixed installations in buildings and other civil engineering works.

Which buildings are involved in CPR?

All buildings and civil engineering works are involved in CPR.

Which applications are involved in CPR?

According to the CPR framework the actual performance level required for any particular regulated application is a National matter.

Basis for country CPR-level decisions can include e.g. Fire risk, Ease of Escape in case of fire or exposed area of cable surface.

How do countries implement CPR?

Currently many countries have their own national fire regulations. This has not allowed for free movement of products in Europe; national laws that contain essential product requirements are not harmonized. CPR rules will change this. The rules will be applied without differences of interpretation by each member state.

What are Notified Bodies?

A notified body is an independent, third-party body recognized by the European Union. CPR includes three types of notified bodies: product certification body, factory production control certification body and a testing laboratory.

Will cable designs change due to CPR requirements?

Depending on the cable type, changes to design may be required to obtain certain Euroclass performance.

Why is CPR important for cables?

Current building construction projects often require many kilometres of installed cabling. High volumes of cabling have been recognised as fire and smoke safety risks, as they are one of the main methods that fire can rapidly spread through a building. Correctly controlling and regulating installed cabling can potentially save lives and minimise building damage in the event of a fire.

What is the Declaration of performance (DoP)?

The DoP is a document in which the manufacturer clearly identifies a product and its performance levels regarding Fire Reaction, and via which he enters into an undertaking regarding his responsibility, with the following information:●DoP number●Product reference●Product description●System for evaluation and certificate of conformity●Identity of the organization notified●Planned product use●The class in the light of the product’s performance declared as to Fire Reaction●The manufacturer’s contact details with the signature of a person entering into the undertaking regarding responsibility on behalf of the Company

By drawing up his DoP, the manufacturer undertakes to guarantee the conformity of the construction product concerned with the performance declared initially and certified by an outside laboratory On the basis of the information set out in the DoP, the user is informed of the characteristics of the cables regarding their Fire Reaction and decides to purchase a product that is suitable for the desired use, from among the products available on the market. The manufacturer informs, and the user selects and is responsible for his choice.

Is the CE marking more or less important than my national quality mark?

The CE-marking will be a pre-condition to place cable for construction works on the market. The relevance of the CE marking under the CPR is the elimination of technical barriers among the Member States arising from the definition of fire performances, as well as the uniform modality to attest the conformity of cables.

Quality Marks cover other aspects of the product, such as mechanical and electrical performances and dimensions, and are unique tools for monitoring compliance with voluntary standards.

Therefore, a comparison between the CE marking and voluntary National Quality Marks is misleading, because they concern two different topics.

What is the responsibility of end users in CPR?

When working with the project team to draw up specifications, end users should refer to the harmonized technical specifications (specifically to the requirements of individual characteristics). When choosing products for construction projects, end users should review the Declaration of Conformity/Performance from the manufacturer.

They must also check national annexes or standard recommendations, which offer guidance about appropriate minimum product performance levels. Compliance with local building regulations should also be followed by end users.

What is the responsibility of integrators in CPR?

Integrators have a list of responsibilities that are similar to those of end users. They should refer to the harmonized technical specifications (specifically to the requirements of individual characteristics) when drawing up project specifications. When selecting products for use in European buildings, integrators should be sure to review the manufacturer’s Declaration of Conformity/Performance.

They must also check national annexes or standard recommendations for guidance on appropriate minimum product performance levels. Compliance with local building regulations should also be ensured.

What is the responsibility of importers in CPR?

Importers are required to follow several steps as part of CPR. First, they must verify that manufacturers have done everything required to comply with CPR rules, including additional requirements as determined by the AVCP rules. Next, importers should make sure that their own name and contact details are visible on theproduct, its labeling or the product’s associated documents; instructions and safety information must also be in the appropriate language of the particular market. When stored or moved, products must not be altered to void compliance. As long as the product is on the market, it should be monitored. Documentation should be kept for 10 years by importers. Importers must take corrective measures when necessary, and cooperate with any requests from authorities.

What is the responsibility of distributors in CPR?

As part of the project team, distributors must ensure that the product is compliant and has all documentation to verify CPR compliance. All instructions and safety information must be in the appropriate language of the particular market.

Distributors should check to see that the manufacturer has made the product identifiable, and that the manufacturer’s/importer’s contact details are visible. If products are stored or moved by the distributor, it must be done in such a way that compliance isn’t altered. Distributors must take corrective measures when necessary, and cooperate with any requests from authorities. When a distributor places a product on the market under its own trade name, or modifies a product in any way, the distributor is then viewed as the manufacturer.